Raster Image Processor

RIP is the acronym for Raster Image Processor and is a system that translates computer documents to a printable format. Just like the graphics card in your computer translates digital code into a viewable image, a RIP is necessary to ‘display’ digital content on paper.

Unlike your desktop printer with a built in translator, commercial printing RIPs requires a lot more horsepower and has to tackle far more technical problems. At the heart of the RIP is the screening engine.

Screening

In traditional multi-color printing we would expose images through color filters and very fine screens to break the continuous tone image (photograph or illustration) into a series of tiny dots. These dots are visible under magnification but at normal reading distances the human eye will blend the colored dots back into a continuous image. With the image broken down to dots and component colors we can now image that to a printing plate and subsequently put ink on paper. A RIP’s screening engine accomplishes the same thing using software. It separates the component colors of an image and then breaks each of those down to a series of different size dots placed on a very fine grid.

Flattening

Before screening can occur the RIP needs to simplify the document. It takes all of the layers of information – text, images, objects, blends, drop shadows and so on – and flattens them down to a single layer. The RIP then examines the flattened document and creates a list of trapping instructions to pass to the separation engine. The RIP applies trapping and separates the component colors which in the case of Four Color Process Printing is Cyan, Magenta, Yellow and Black. Finally the RIP can apply screening to each of the separations.

Imaging

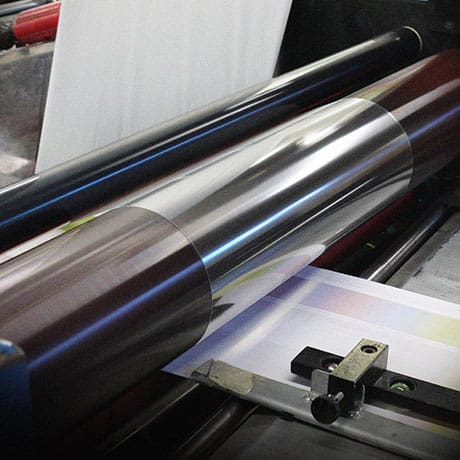

The last job of the RIP is to compress the separation files and send them to a plate setter or CTP (Computer to Plate) device. This will be the subject of a future ‘What is…’ post.

Our pre-press experts are an indispensable resource available to you on any project. We are only a phone call or an email away: 770-664-8199 / prepress@advancedpf.com.